TAJIMI

CUSTOM TILES

Story

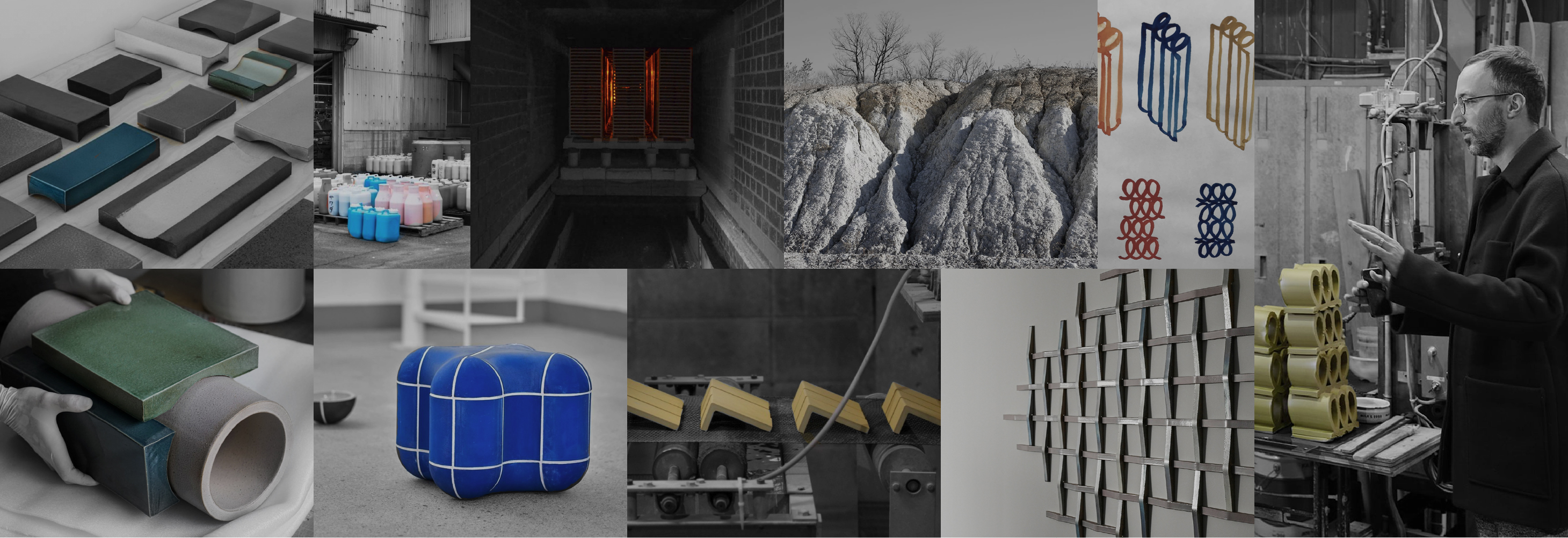

TAJIMI CUSTOM TILES appointed designer David Glaettli as its Creative Director and was launched as a new brand by X-iS in 2019.

Building on Tajimiʼs exceptional materials, skilled craftsmanship, and well-established production capabilities, we offer bespoke tiles that provide unparalleled freedom in design and production, from shape and texture to glaze colors and materials.

Thanks to Tajimi's unique firing techniques and glaze expressions, we can create original designs and customize existing products in small batches. We have collaborated on projects with leading designers and architects, including Ronan Bouroullec, Kwangho Lee, and Max Lamb. Tajimi's bespoke tiles have had a revolutionary impact on architectural spaces and continue to expand their possibilities worldwide.

Crafting diversity rooted in tradition and history

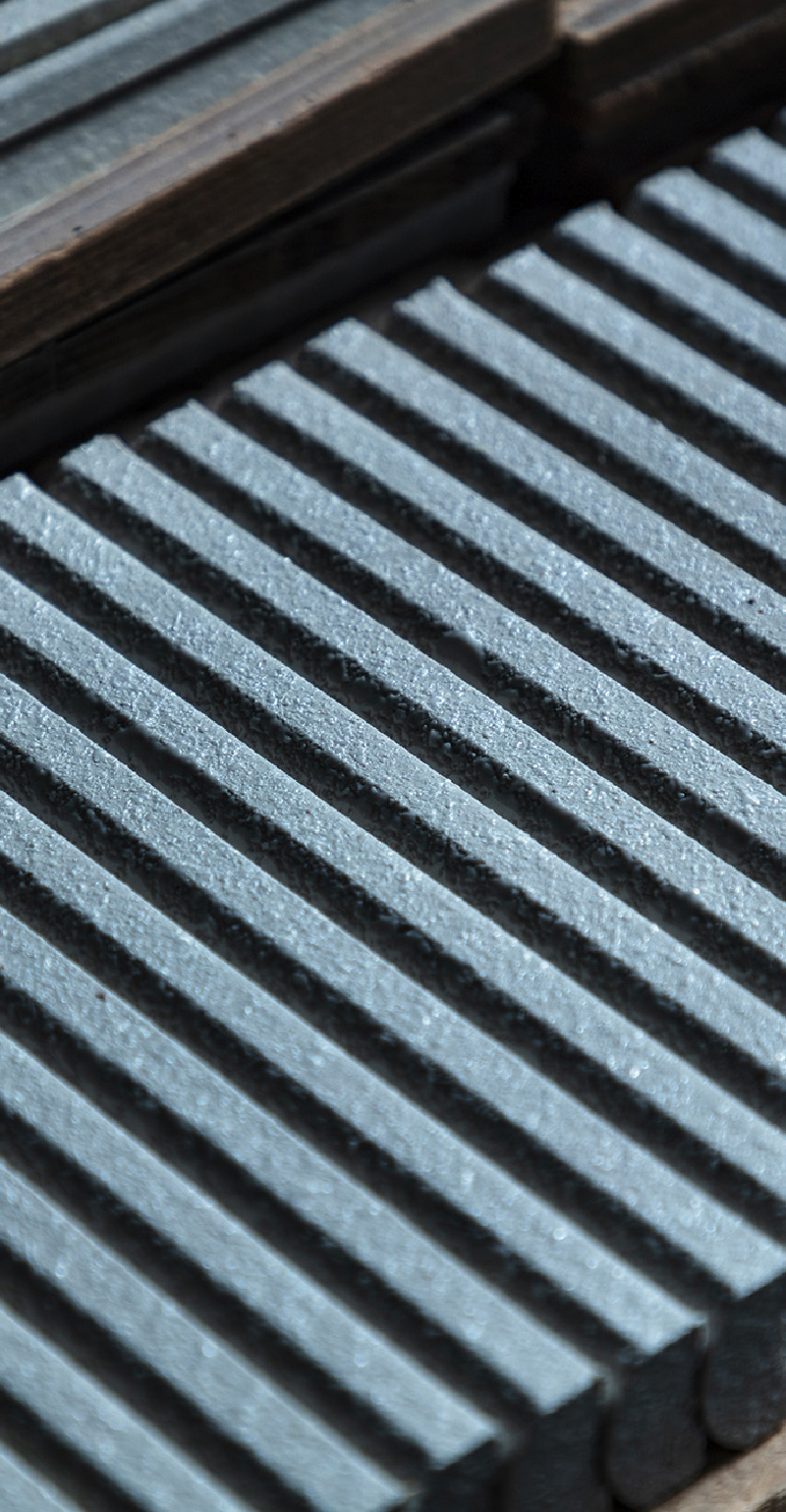

Tajimi City, located in the southern part of Gifu Prefecture.

This region, known for its soil rich in high-quality clay minerals, saw the emergence of pottery culture around 1,300 years ago. The birth of Mino ware, one of Japan's most historic and representative ceramics, significantly expanded the potential for craftsmanship in the Tajimi area. These circumstances, paved the way for the beginning of tile production in the early 20th century.

Tile production in Tajimi continues to thrive, with the region leading the country in total output. As for mosaic tiles, this region accounts for 90% of the national production. However, the distinctive feature of Tajimi tiles goes beyond their overwhelming production capacity. The craftsmanship in Tajimi is supported in a multifaceted way by specialized manufacturers. While traditional Japanese firing techniques and the rich variety of glaze expressions have almost disappeared in other regions, Tajimi continues to preserve the equipment and production methods that make this possible, further defining the uniqueness of the area.

Through numerous conversations with architects and designers, Creative Director David Glaettli has come to strongly believe that tiles are a material capable of further enhancing the unique characteristics of buildings and spaces. Leveraging the unique expertise found in Tajimi, he launched Tajimi Custom Tiles in collaboration with X-iS Co., Ltd., a company dedicated to bringing refined designs to life. CUSTOM TILESをスタート。

Together with Tajimi's best partners, who excel in specialized skills, we will actively promote the charm and appeal of tiles to the world.

What only Tajimi can offer to the world

David Glaettli, Creative Director of Tajimi Custom Tiles, was born in Switzerland in 1977. After studying industrial design, he established Japan as his base of operations in 2008. He has carefully considered how designers' and manufacturers' skills can best serve users, offering precise guidance on the significance of design for the future.

Besides this project, he has been involved in numerous other projects that showcase Japan's technological prowess to the world, such as 'KARIMOKU NEW STANDARD,' '2016/,' and 'Sumida Contemporary.'

SOSEI BY

RONAN BOUROULLEC

A series of objects, resembling vases, created using the extrusion molding technique employed in tile manufacturing in Tajimi. By attaching objects to the cylindrical base, geometric shapes and compositions of glaze colors are created. The harmonious, rich glaze colors, typical of Japanese ceramics, pay tribute to their beauty.

- Ronan & Erwan Bouroullec

- The French designers Ronan and Erwan Bouroullec, brothers born in 1971 and 1976 in Quimper, Brittany, have been working together since 1999. Their creative work spans a wide range of fields, from industrial design and crafts to mass-produced goods, research activities, and public spaces, gradually infiltrating our lives. Their career is also marked by collaborations with artisans who carry forward techniques passed down through generations, working with international companies and craftsmen from Europe to Japan. Through various research activities, they have also collaborated with some of the world's most renowned museums.

WORKING TILE BY

MAX LAMB

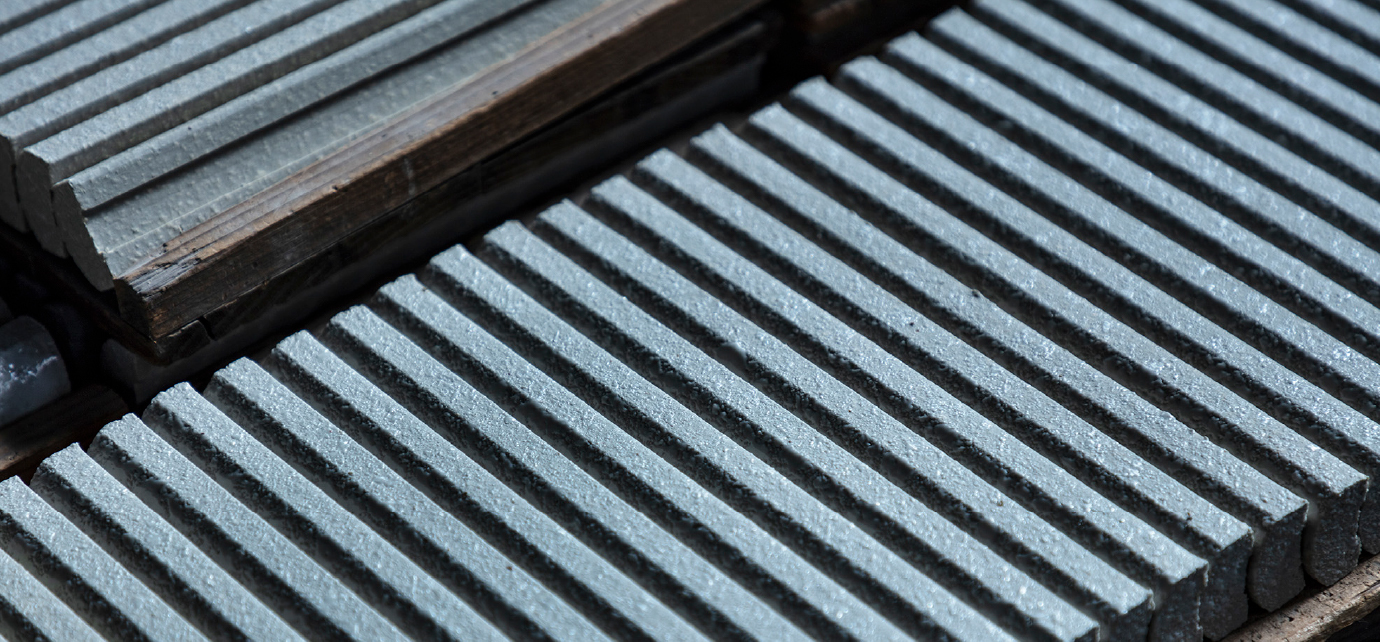

Building on Tajimi's unique tile manufacturing system, what should Tajimi Custom Tiles strive to achieve? In exploring this question, Max Lamb created 3D tiles in a variety of shapes. By combining these three-dimensional tiles like a puzzle, he formed a range of items—such as flower vases, low tables, benches, and partitions. To bring out the full charm of the clay, he carefully selected the materials and used special glazes to revive the subtle, deep colors found in traditional Japanese tiles, giving them a modern twist. Furthermore, the voluminous, three-dimensional shapes are created through casting.

- Max Lamb

- Born in 1980 in the UK, Max Lamb spent his childhood exploring the natural surroundings of Cornwall's countryside with curiosity. After studying three-dimensional design at Northumbria University, he continued his studies in product design at the Royal College of Art in London. He became independent in 2008. While working as a designer, he also applies his deep knowledge of materials, exceptional shaping skills, and craftsmanship to create a wide range of handmade products. He often combines everyday items with new materials and finds rational solutions through experimental approaches, a quality that has made him known for his straightforwardness and intellectual sensibility.

TIDE by

Kwangho Lee

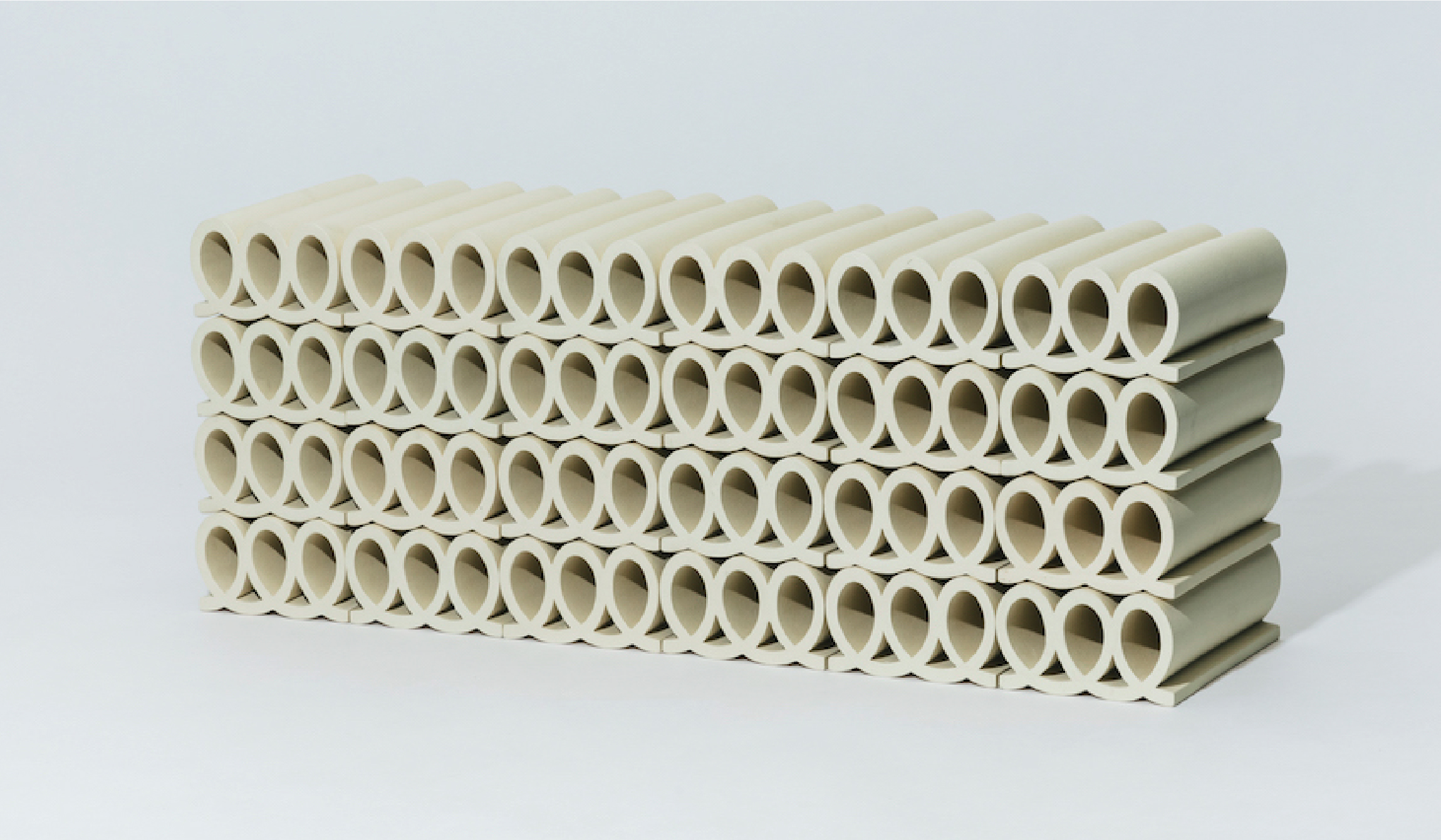

Kwangho Lee, who focused on Tajimi's unique extrusion molding technology, proposed various functions by designing a loop-shaped module that allows for different molding lengths. The modules can be stacked both vertically and horizontally, and depending on how they are arranged, various configurations such as walls and benches become possible.

When the modules are lined up in a row, a loop pattern, reminiscent of something hand-drawn, appears continuously, creating a rich texture that resembles knit fabric. 'Knit' is also a key theme in Kwangho's creative work, and he has previously created many pieces using a variety of materials and scales. In this project, the design captures the inherent nature of clay, which starts off soft and gradually becomes firmer during the manufacturing process.

- Kwangho Lee

- Born in 1981 in South Korea, Kwangho Lee studied metal crafts and design before establishing his own design studio in Seoul. Influenced by his grandfather, a farmer who made various everyday items from materials around him, Lee developed a passion for creating things with his own hands from a young age. This experience can be seen as the foundation of his creative ideas and style. He discovers, reexamines, and reinterprets subtle phenomena hidden in everyday landscapes, carefully analyzing material properties and joining techniques to uncover new possibilities in design. He has worked with a wide range of materials, including expanded polystyrene (EPS), PVC, marble, copper, enamel, iron, and clay.