Decorative Tiles

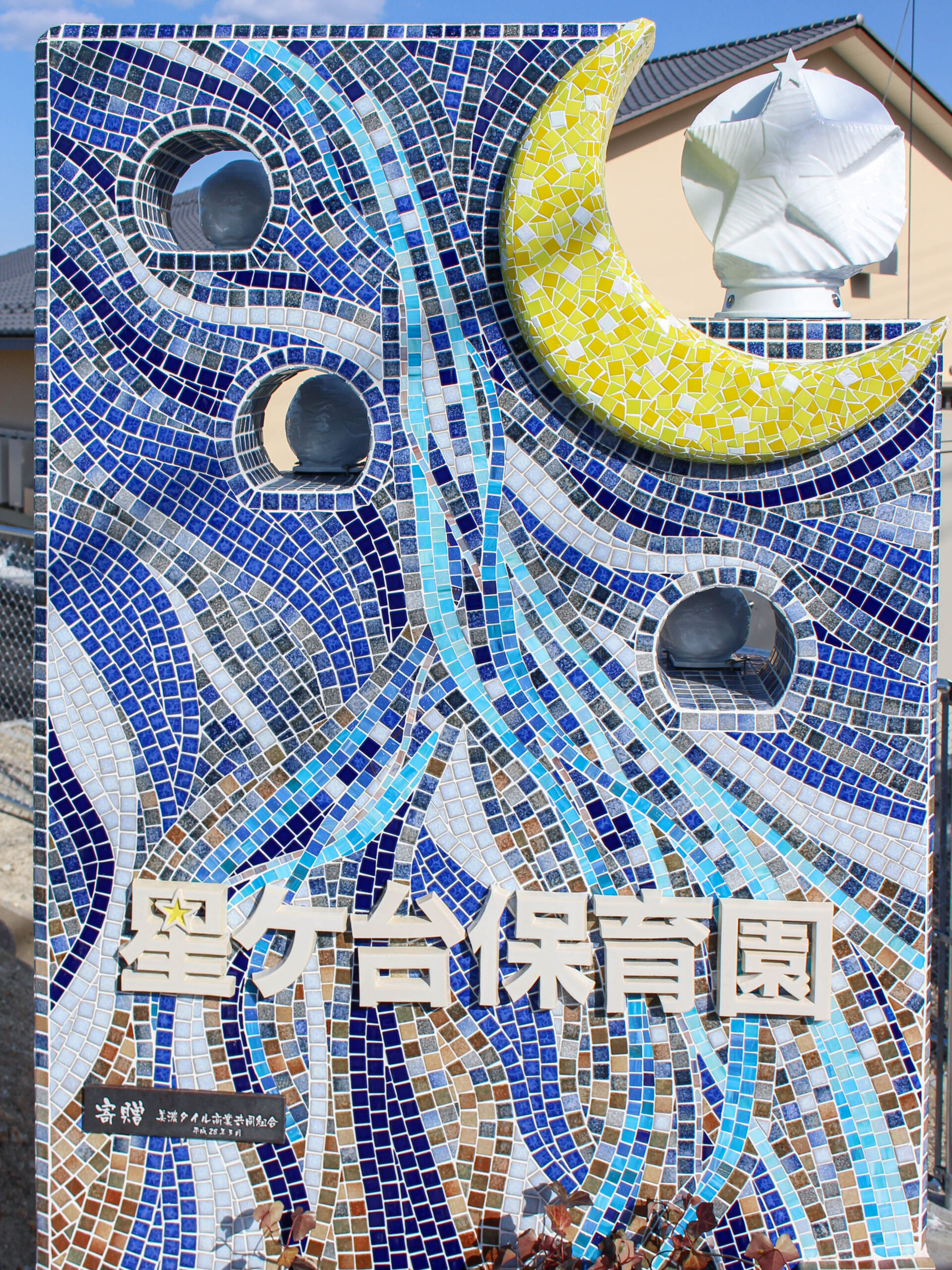

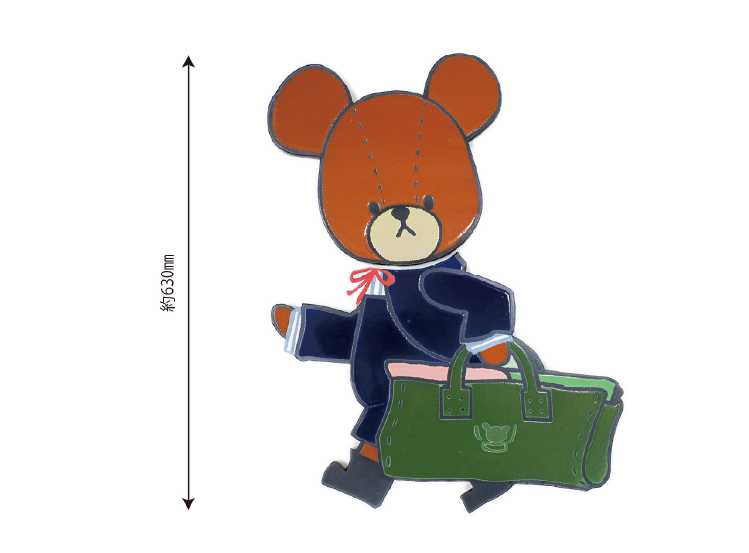

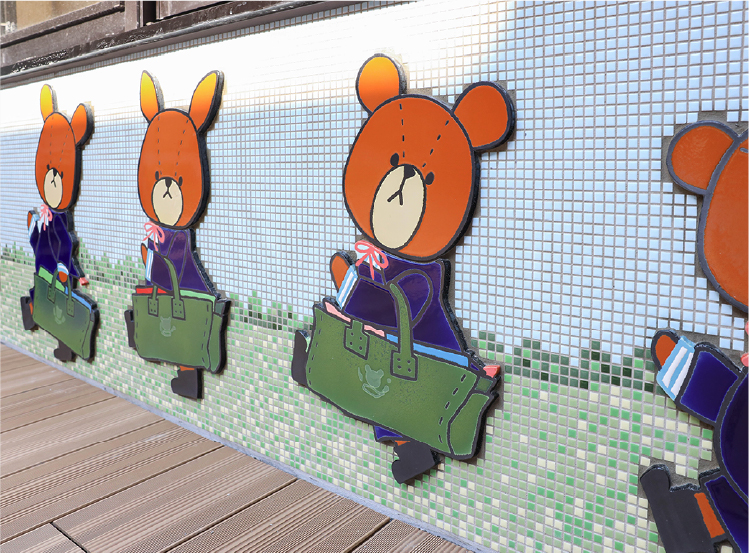

Tiles as the eye-catching feature of the space

Based on the intended use and situation, we will propose the most suitable plan and technique. Thanks to our integrated in-house production, we can make any necessary small adjustments. We provide 100% original picture tiles that faithfully bring your envisioned design to life, ensuring the final result fulfills your expectations.

Characteristics of decorative tiles

Decorative tiles feature delicate patterns and colors that are brought to life through artisan craftsmanship or transfer techniques. With custom designs, you can add a unique charm to any space.

Techniques for Decorative Tile Art

We use three distinct techniques in-house, each with its own unique features. Based on your needs, we'll recommend the best technique, and we can also combine different methods. Contact us for more information.

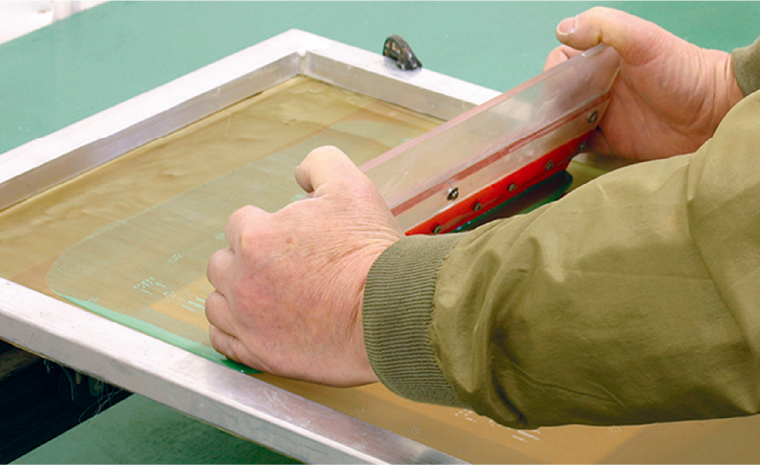

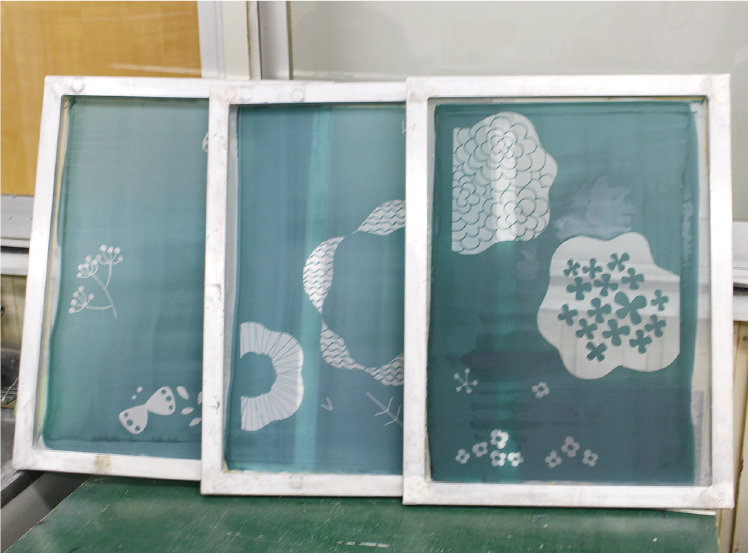

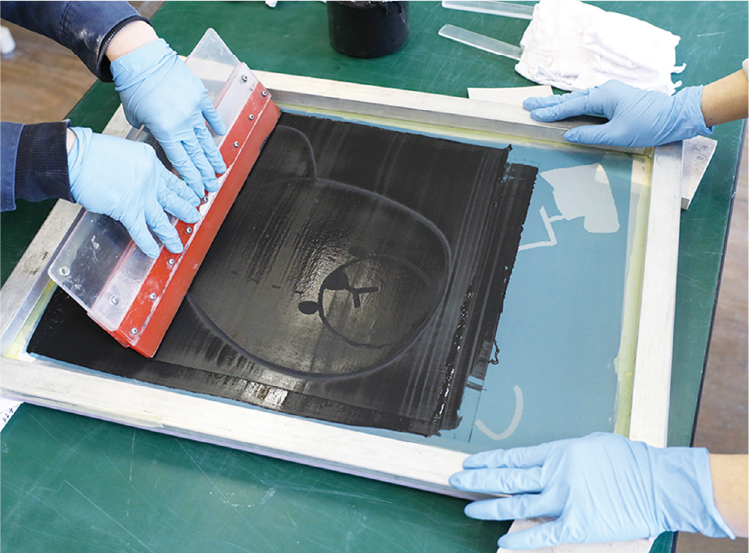

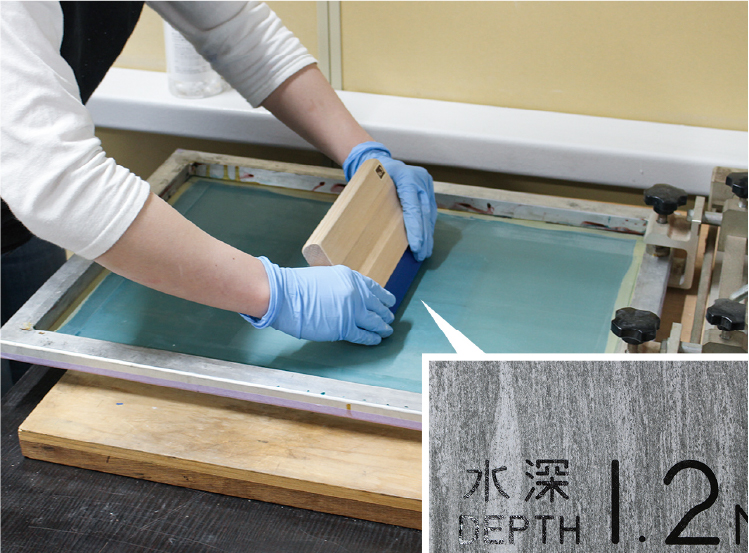

Silkscreen technique

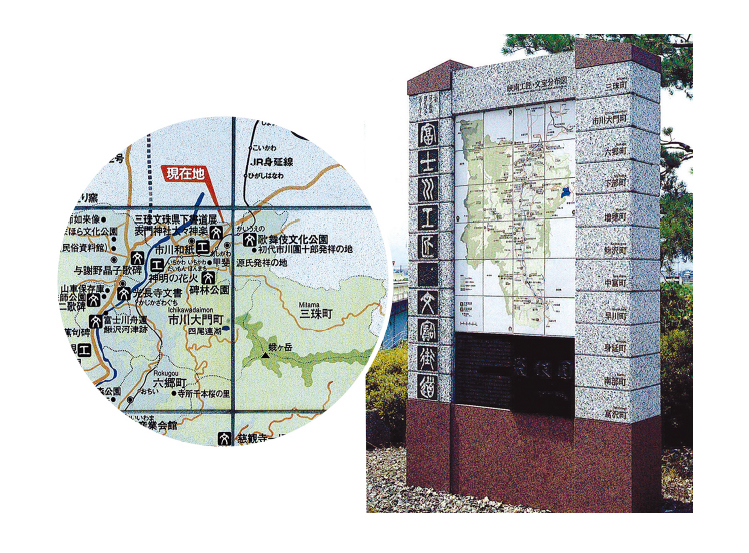

Our unique technique begins with printing an oil-based water-repellent agent onto the raw surface of the tile using the silkscreen method, followed by a water-based glaze. The surface tension causes the glaze to rise, creating a distinctive texture with about 1mm of relief. This process results in highly durable, weather-resistant tiles that are ideal for a variety of applications.

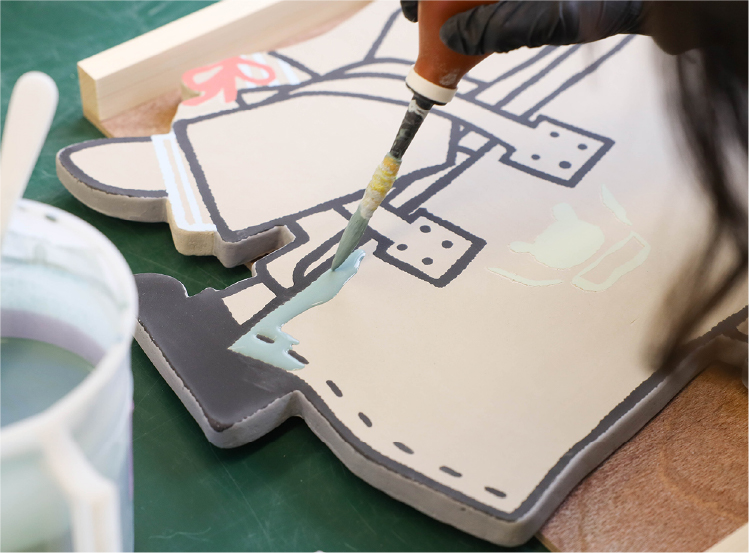

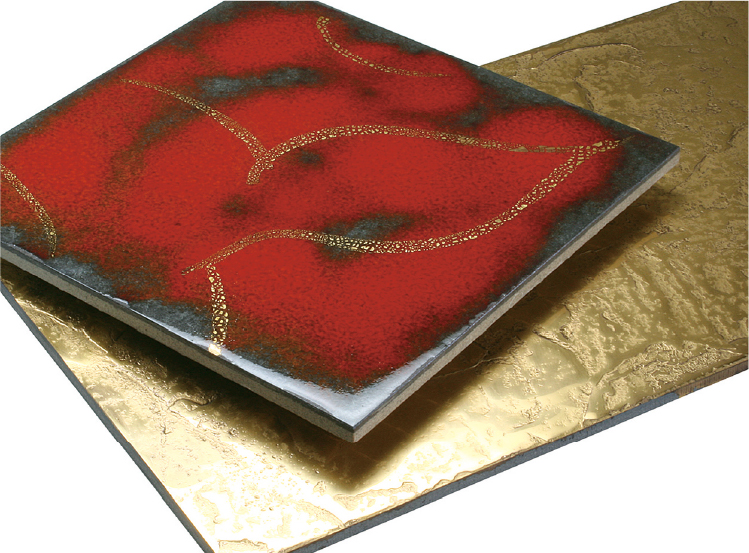

Overglaze decoration technique

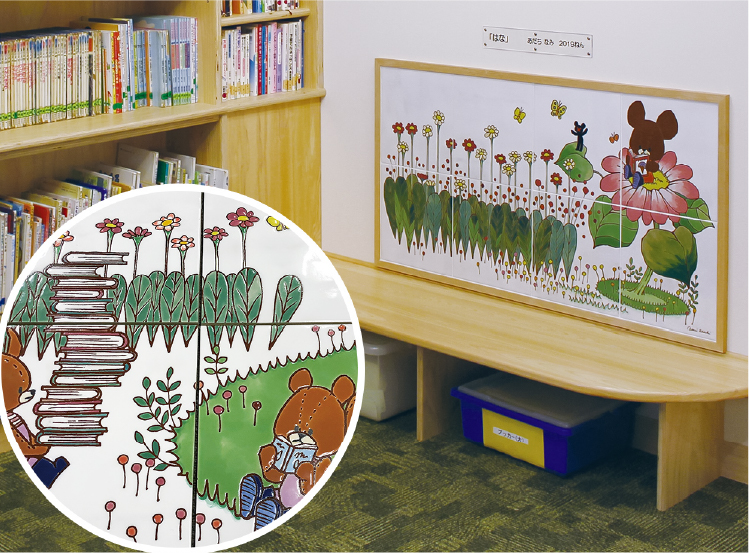

In the overglaze decoration technique, oil-based paints are used to create expressive brushstrokes, making it ideal for decorative tiles that showcase vibrant colors. When reproducing artwork, we pay close attention to faithfully capturing the original artist’s intent.

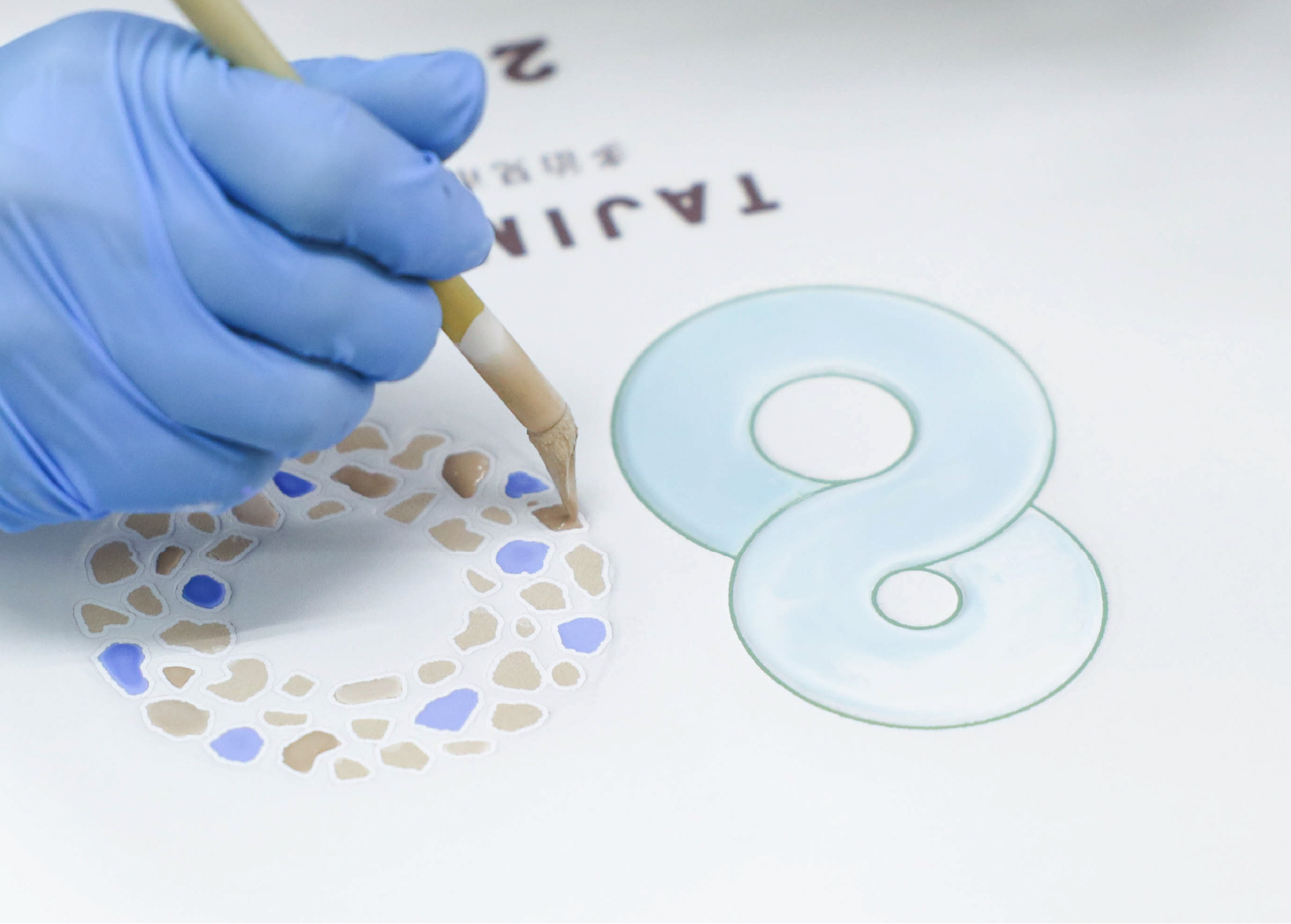

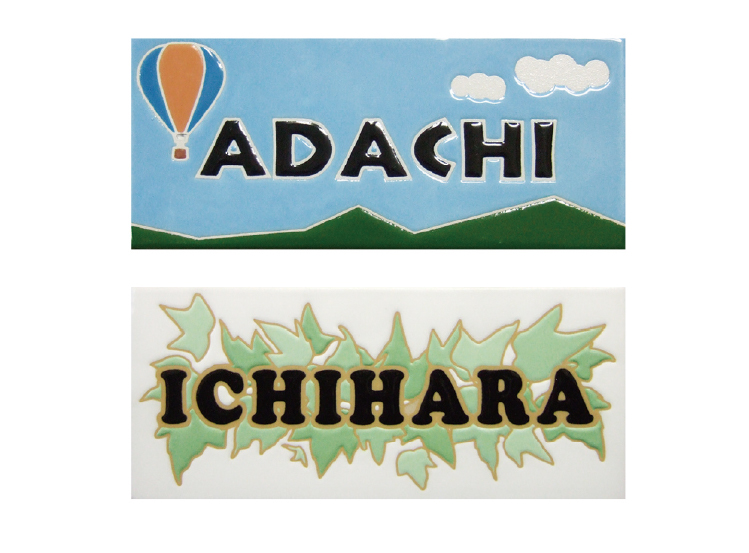

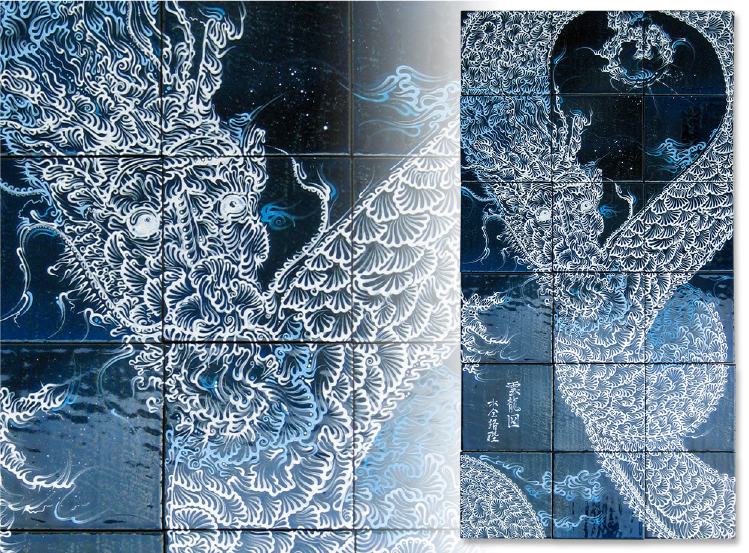

Transfer technique

Our newly developed transfer technique offers rich color tones and excellent image reproduction, including photographs. It is highly durable, weather-resistant, and wear-resistant, and now allows for production starting from a single piece.

Characteristics of each technique

| Silkscreen technique | Overglaze decoration technique | Transfer technique | |

|---|---|---|---|

| Firing | Fired once at high temperature (1250℃) | Fired twice at low temperature (800℃) | Fired twice at low temperature (800℃) |

| Expressivity | △ Exceptional reproduction of line art and illustrations |

○ Gold and platinum firing possible |

◎ Excellent image reproduction |

| Texture | ◎ Texture can be expressed by glaze thickness |

○ Brushstroke reproduction possible |

△ Smooth surface |

| Weather resistance | ◎ Ideal for outdoor walls |

△ Recommended for indoor use |

△ Suitable for outdoor wall use |

| Abrasion resistance | ◎ Ideal for outdoor floorings |

× Not suitable for flooring, even indoors |

× Suitable for outdoor flooring |

| Productivity | △ Production is limited to one piece at a time. |

△ Production is limited to one piece at a time. |

○ Reproduction possible with transfer sheet |

Silkscreen technique

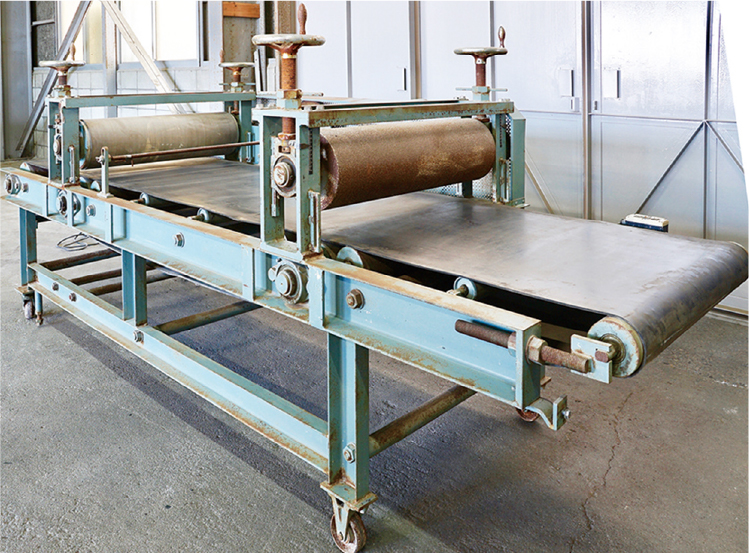

This technique involves printing oil-based water-repellent ink onto the unfired tile, followed by the application of a water-based glaze with a brush before firing. This unique decorative tile method, not found in other companies, uses surface tension to create approximately 1mm of unevenness on the glaze. It excels in both weather and abrasion resistance, making it an ideal solution for a wide range of applications.

The standard process of the silkscreen technique

The silkscreen process for special sizes, shapes, etc.

Overglaze decoration technique

This technique begins by firing the tile, then drawing a design on it before re-firing at around 800℃. Compared to high-temperature single firing, it's ideal for designs that focus on color development. It's particularly suited for delicate materials like gold and platinum, which require lower firing temperatures.

Created by: Yasunori Kimata

Transfer printing technique

The transfer sheet is applied to a pre-fired tile and then fired again at around 800℃. This technique excels at reproducing images, such as photographs, which is difficult with other methods. It is also suitable for large quantities, such as for novelty items, as it allows for duplication. While low-temperature firing results in vibrant color reproduction, it does slightly compromise weather and abrasion resistance.

Transfer Techniques Process