Ornaments

Decorative elements that combine both sophistication and beauty

These decorative elements are crafted from ceramics and other materials and are used in the adornment of both building exteriors and interiors. At X-iS, we specialize in fully customized, made-to-order ornaments, crafted using casting and hand-carving techniques.

Characteristics of Ornaments

Ornaments can be created as a single molded piece, making it possible to produce large-scale decorative items. Another key feature is the possibilty to create decorations with an overwhelming impact by combining different parts. With slip casting, we can create pieces as large as 800mm x 400mm, and also include intricate designs and custom carvings.

Ornaments Creation Process

01 About Drain Casting

Drain casting (also called slurry casting) is one of the traditional techniques used in ceramics production. The process involves pouring slurry into a plaster mold, removing the excess, and then taking off the mold to shape the piece.

This technique is ideal for creating three-dimensional ceramic pieces with hollow interiors, such as teapots and vases. Today, only a few manufacturers and suppliers still use this method, making it a valuable craft.

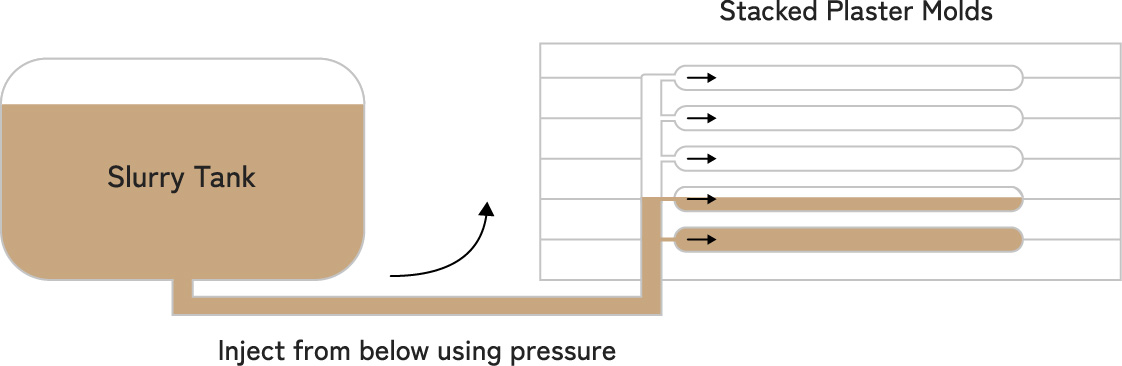

02 About Slip Casting

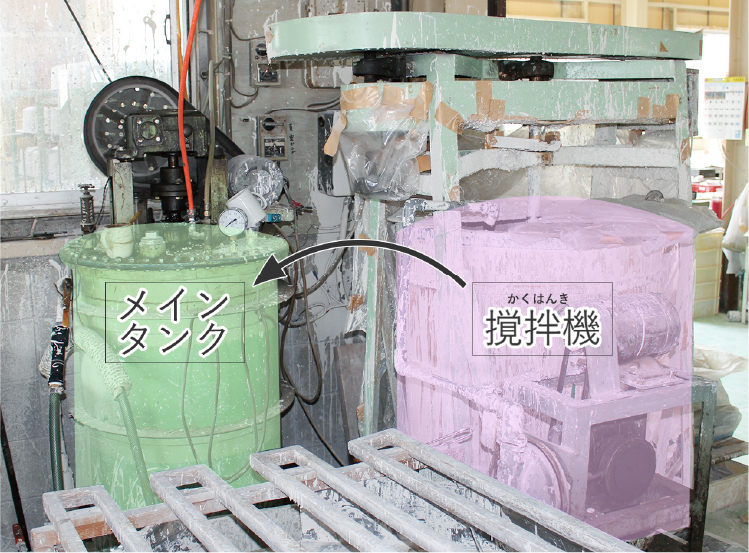

Slip casting is a method where slurry is poured into a stacked plaster mold, with pressure applied from below to ensure even distribution. This technique is applied in tile production for designs with unique shapes that cannot be made using extrusion or press molding.

This process requires careful manual work, such as removing the piece from the mold and trimming any excess, making it a highly labor-intensive and skillful method of molding, but the result is a beautifully intricate finish.