Water Jet Art

A technique for cutting through all kinds of materials

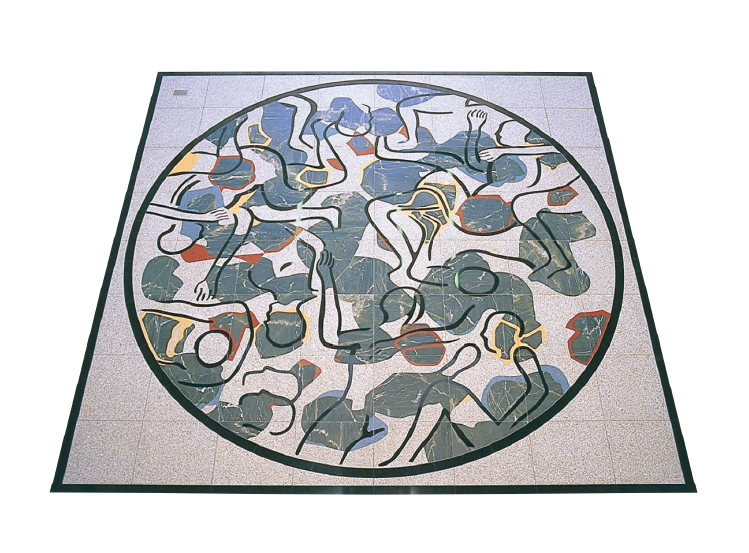

Because it beautifully expresses curves, it is ideal for creating company and store logos, as well as for curve-based intricate designs artwork. We carefully reproduce your custom orders.

Characteristics of Water Jet Art

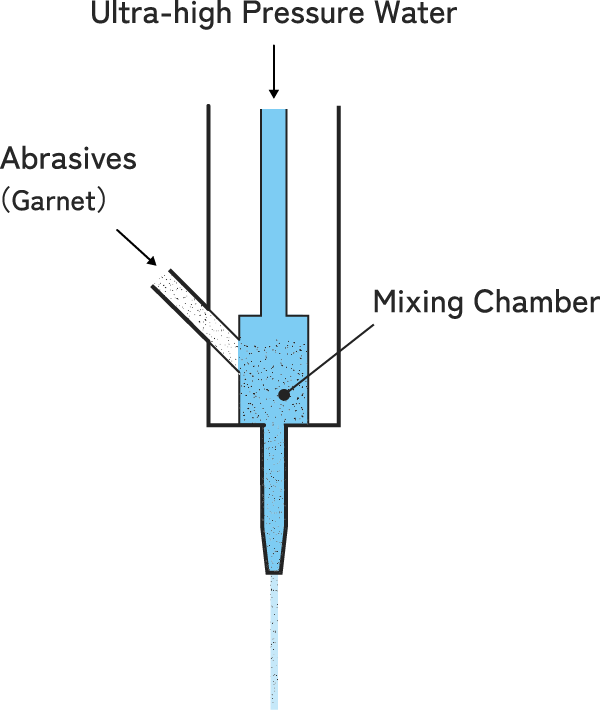

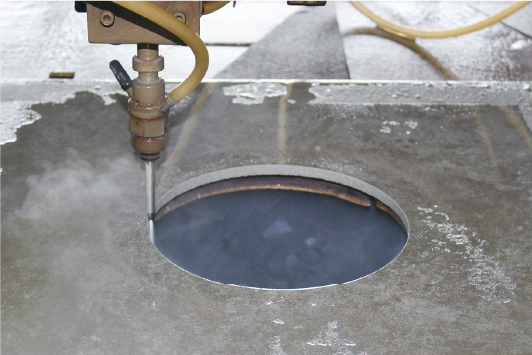

Water jet cutting technology involves mixing water with abrasives and spraying it at ultra-high pressure through a small nozzle (about 1mm in diameter) to cut through the material. This technique can cut a wide range of materials, including stone, tile, and metal, and is ideal for creating curves, intricate designs, as well as cutting and drilling holes.

Water Jet Art Creation Process

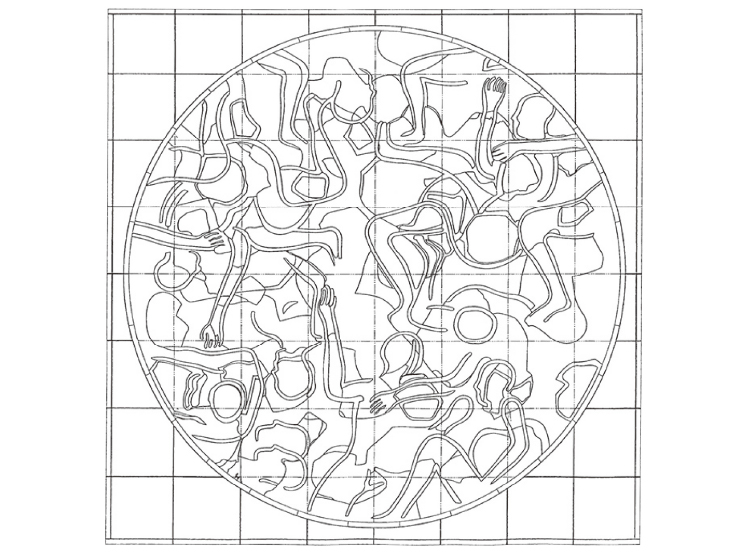

Example of the production process

Damascening is a traditional craft technique that involves inlaying a different material into a base material. Using water jet technology, this technique allows for the seamless combination of various materials. By combining marbles of different colors and inlaying letters or patterns, it’s possible to create highly artistic works.

01 Advantages of Water Jet

①Minimal heat-affected zone during cutting

At the beginning of the cut, a significant impact occurs, which can lead to some material loss. However, after that, the process generates low surface stress, allowing the cutting to proceed without affecting the material.

②No damage to the material

Thanks to the minimized friction, materials that are sensitive to heat can also be cut. Additionally, it can easily cut brittle and hard materials.

③No dust is produced

This method uses only water and sand (as the abrasive material) for tile processing, generating no dust and having no harmful effects on the human body or the environment.

④Capable of cutting various shapes

Cutting is done using CAD data, allowing for precise cuts and cutouts in any shape, starting from any point. Additionally, we can cut both 2D and 3D shapes, as well as process large tiles that are typically difficult to handle.

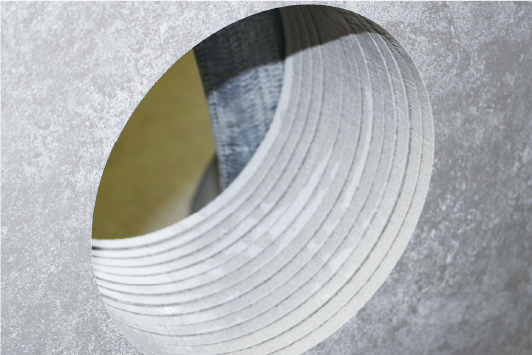

02 Combination of techniques that expand creative possibilities

By combining techniques like 'tumbled marble art' and 'sandblasting,' we can expand creative possibilities. If the thickness of different materials isn't uniform, we use materials like cut granite as a height adjuster to ensure the design is faithfully reproduced.

03 Finishing

All listed products come with a 'polished finish,' but we also offer an option for a 'water-polished finish.'

Product Introduction

We have many other items available. Please don't hesitate to contact us.

WJ-1

- Size:φ800mm×T20mm

- Reference price:¥255,000

WJ-2

- Size:φ800mm×T20mm

- Reference price:¥255,000

WJ-3

- Size:1,600mm×800mm×500mm

- Reference price:¥170,000

WJ-4

- Size:φ500mm×T20mm

- Reference price:¥160,000

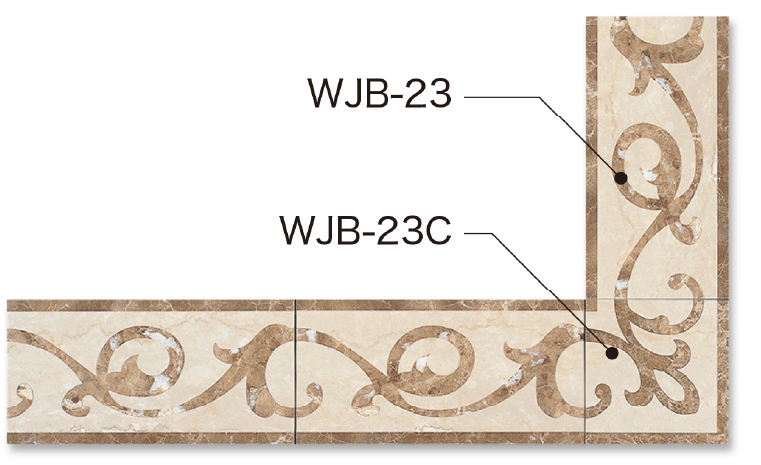

WJB-23 / WJB-23C

- Size:H300mm×W150mm×T13mm / H150mm×W150mm×T13mm

- Reference price:¥18,000 / ¥10,400

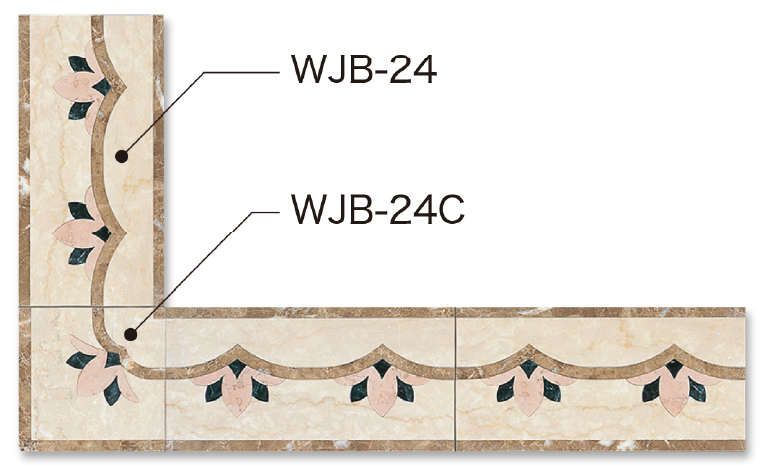

WJB-24 / WJB-24C

- Size:H300mm×W150mm×T13mm / H150mm×W150mm×T13mm

- Reference price:¥18,000 / ¥10,400