About Us

Tile crafting professionals

At X-iS, we avoid overdone creations and aim to make the most of our high-quality materials to create natural beauty tile craftsmanship. While ensuring quality, we would like to assist you in creating a space with depth and character that fulfills you every time you look at it.

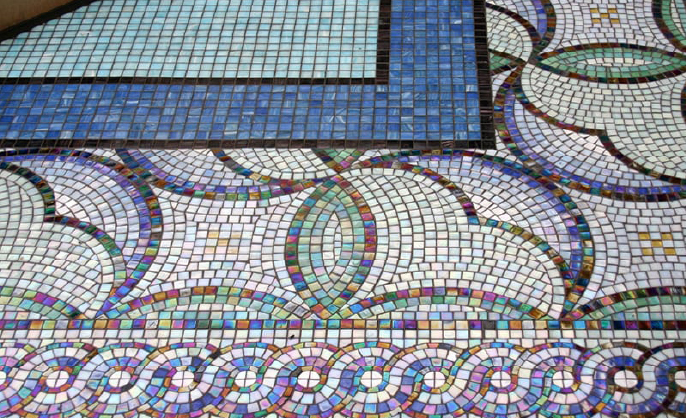

X-iSDedication to mosaic art creation

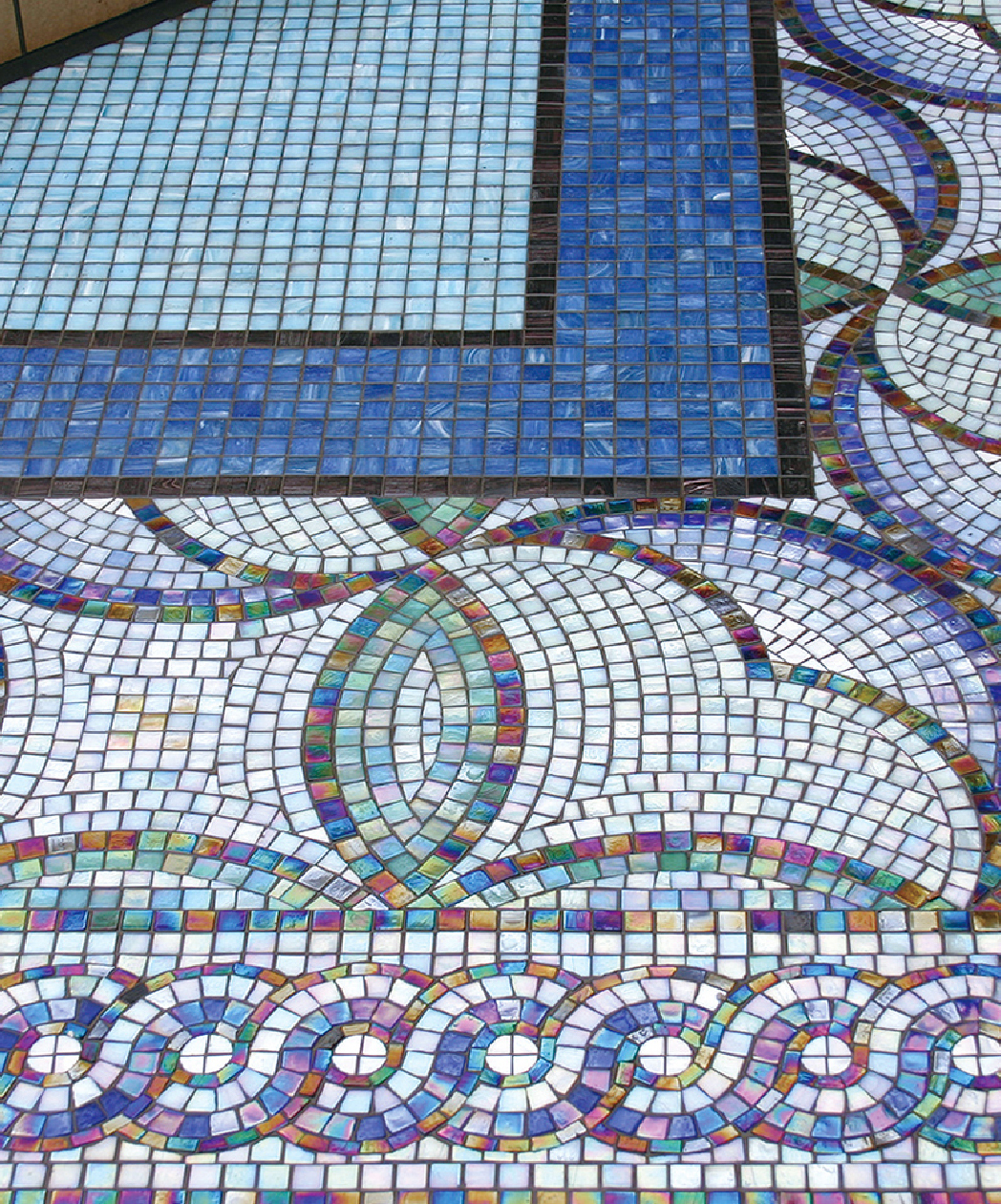

At our company, we make the most of the high quality of the tiles, creating tile art that highlights their natural beauty without overcomplicating the design.

We ensure the quality of every piece, with the goal of helping you in creating a space that fulfills you every time you look at it.

We pay close attention to templates and layout sheets for installation. You can rest assured, as we handle everything in-house, from the initial proposal to final delivery.

Expertise in custom tile solutions

From prototype creation using modeling machines to molding, glazing, and firing, all processes are carried out in our company's lab, allowing us to produce custom tiles even in small quantities.

Not only do we accommodate your design, but we also respond to your budget and delivery time requests. Please feel free to contact us.

Challenge to reduce environmental impact

In ecorevo®︎, which has successfully produced tiles from urban and industrial waste materials, we have managed to reduce carbon dioxide emissions through low-temperature firing without compromising quality.

Would you like to join us in creating building materials that not only have minimal environmental impact but also offer excellent functionality?

Three key strengths of X-iS

ADVANTAGE 01

Materialization of an image

Starting with the customer’s initial design, we manage the entire process, from design proposals and custom tile development to tile art production. This is one of our company’s key strengths.

ADVANTAGE 02

Our market is global.

With the motto 'Bringing the best of Japan to the world and the best of the world to Japan,' we leverage the extensive network we’ve built with countries such as the U.S., Europe, India, China, and Southeast Asia to offer effective solutions tailored to our clients' ideas and budgets.

ADVANTAGE 03

R&D

Since its opening in 2019, X-iS Lab has been equipped with various equipment, including a vacuum extruder, a milling machine, a roller hearth kiln, and an Eirich intensive mixer, among others. We are actively developing the next generation of tiles. One of the main projects that the EcoRevo® team is focused on is the development of recycled tiles made from waste materials.

ADVANTAGE 01

Materialization of an image

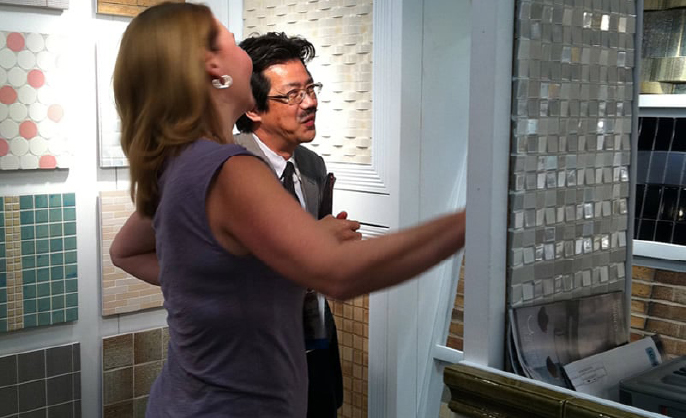

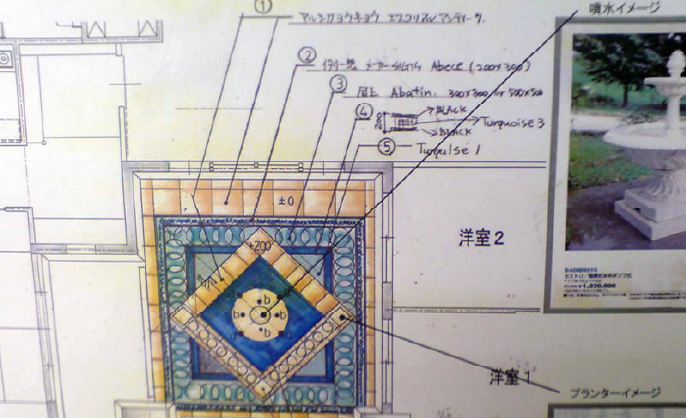

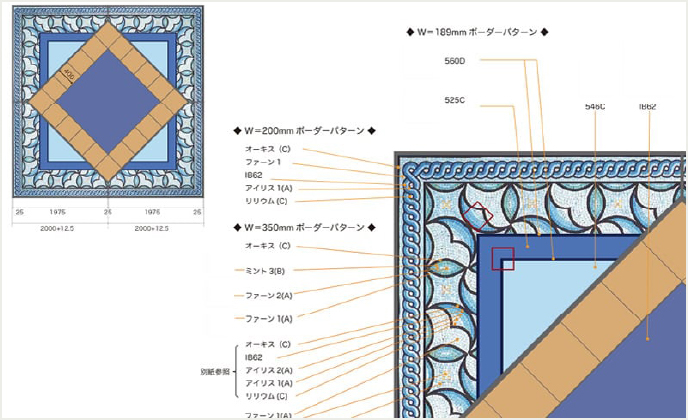

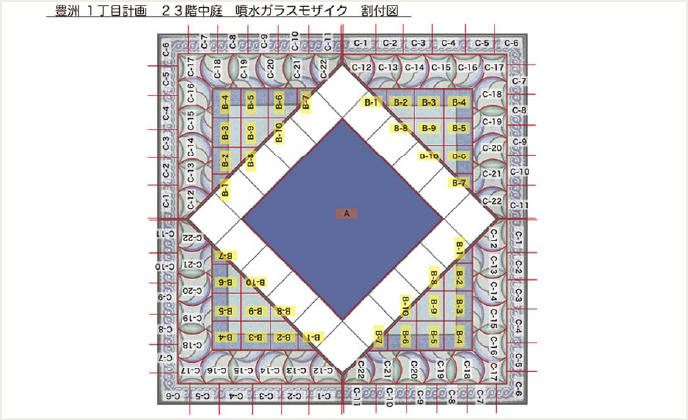

At X-iS, we use tools like CAD drawings to create presentations that allow our customers to visualize the final design and review our proposals. Unlike outsourcing, the entire process is handled in-house, facilitating direct communication between our team and the client.

Considering factors such as your budget and the intended location, we carefully evaluate materials, manufacturing methods, and all other relevant details before recommending the best option. We also provide cut tile samples, allowing our customers to feel the texture and get a sense of how it will look after its installation.

Once the plan is decided, we create the tile layout drawings and then pass the production work to our in-house workshop. Thanks to the close teamwork within our company, we’ve been able to meet a wide range of needs, including the production of ceramic walls, mosaic art, and custom tiles. Especially for decorative tiles, we handle everything in-house—from screen printing to hand painting and firing—resulting in significantly reduced lead times and improved reproduction of designs.

The well-established support system behind 'CRAFT&ART' is what makes X-iS truly stand out.

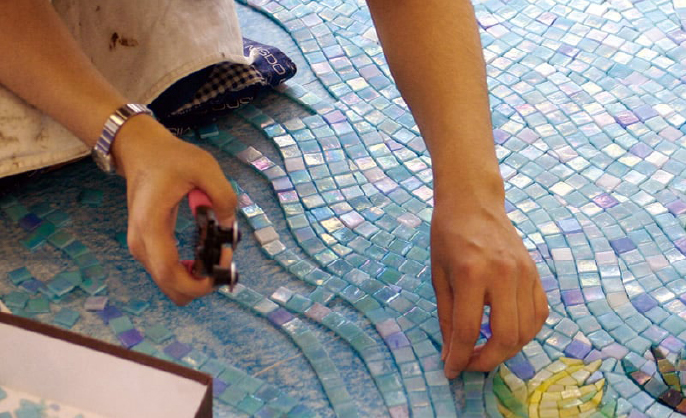

Mosaic Art production process

01Presentation

-

Concept illustration provided by the customer -

Our presentation including color and tile placement instructions -

Tile layout / Approved layout and installation instructions

02Production process

03Completed work photos

Park bench production process

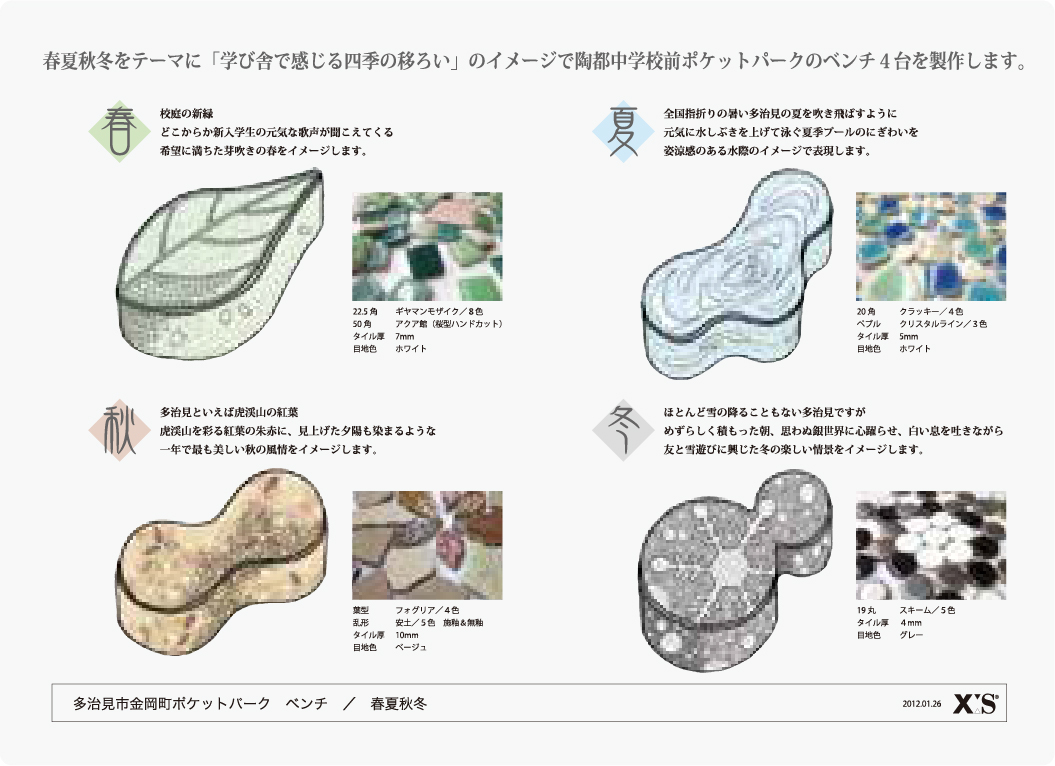

01Design Plan

Four Seasons design plan

Based on the request to install four benches in the park, illustrations representing the four seasons were created, and each different design was suggested.

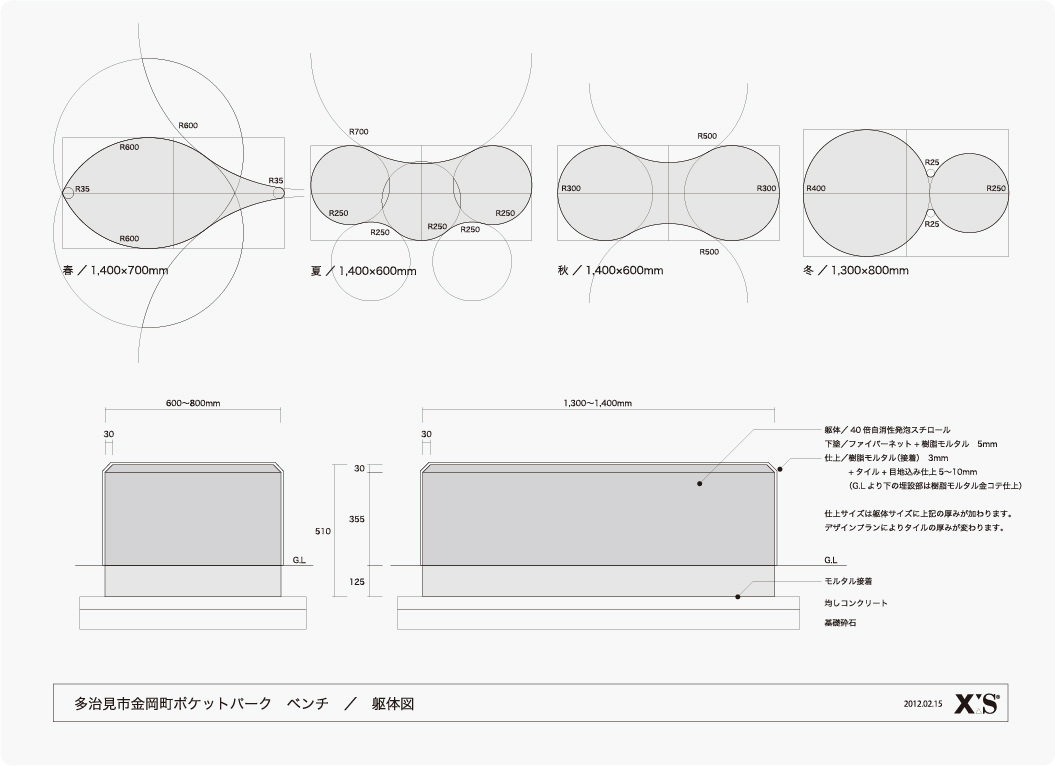

Structure design plan

A structure made from a lightweight, easy-to-transport, and easy-to-install special foamed material, finished with tiles, is proposed. Everything, from structural strength tests to the construction method, is considered, and design plans are created.

02Craft

Structure finish / Substrate layer

To reinforce the structure made of special foamed material, a tile substrate is prepared.

Picture tile

The prototype of a tile featuring the mascot of Tajimi City in Gifu Prefecture was created through multiple iterations. After this, the silhouette of the mascot is carved onto the square-shaped base.

Grouting

Normally, a contractor handles the tile installation and grouting on-site, but our company manages everything in-house, from preparing the substrate to tile installation and grouting.

03Completed work photos

-

Completed work / Spring -

Completed work / Summer -

Completed work / Autumn -

Completed work / Winter

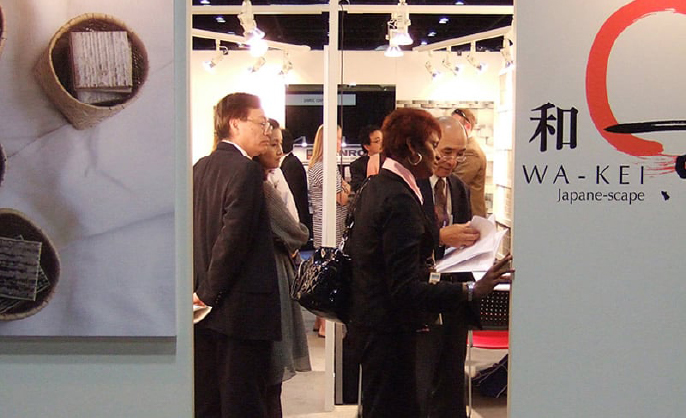

ADVANTAGE 02

Our market is global.

Bringing the best of Japan to the world

and the best of the world to Japan

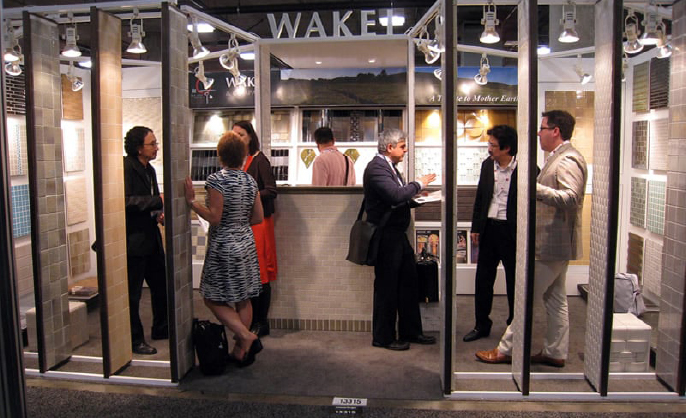

Based on this belief, X-iS established a branch office called WAKEI & CO. in Los Angeles, USA, in March 2007, which also serves as a promotional office.

With this in mind, we began establishing connections not only in the United States but also in European countries like Italy, as well as in Southeast Asia. Our goal is to develop a business model where both exports and imports play an equally balanced role.

As we continued to accumulate achievements, we took advantage of the connections we have established to specialize in offering Made-in-Japan products to overseas markets, while offering high-quality products from around the world to Japan. What about using tiles with beautiful textures and expressive designs to enhance and make your spaces more attractive, all within an adjusted budget?

Leave it in X-iS's hands.

Interactions at overseas exhibitions

ADVANTAGE 03

R&D

Recycled tile R&D

ecorevo® is a team dedicated to developing recycled tiles using various waste materials as raw materials. This major initiative from our company aims to contribute to the SDGs and address waste and environmental issues by promoting sustainable building materials to society.

At ecorevo, we have successfully developed 'earth-friendly tiles' with over 80% recycled raw materials, setting a new standard compared to traditional recycled tiles. Additionally, through the use of low-temperature firing, we have reduced CO2 emissions by up to 33%. From here on as well, we will continue researching and developing new tiles made from recycled materials.